Understanding the Functionality of Membrane Layer Switches for Customer User Interface Instruments

The functionality of membrane switches represents a significant development in customer interface design, combining performance with visual flexibility. As industries increasingly prioritize user experience, recognizing the subtleties of membrane layer button technology ends up being vital.

What Are Membrane Buttons?

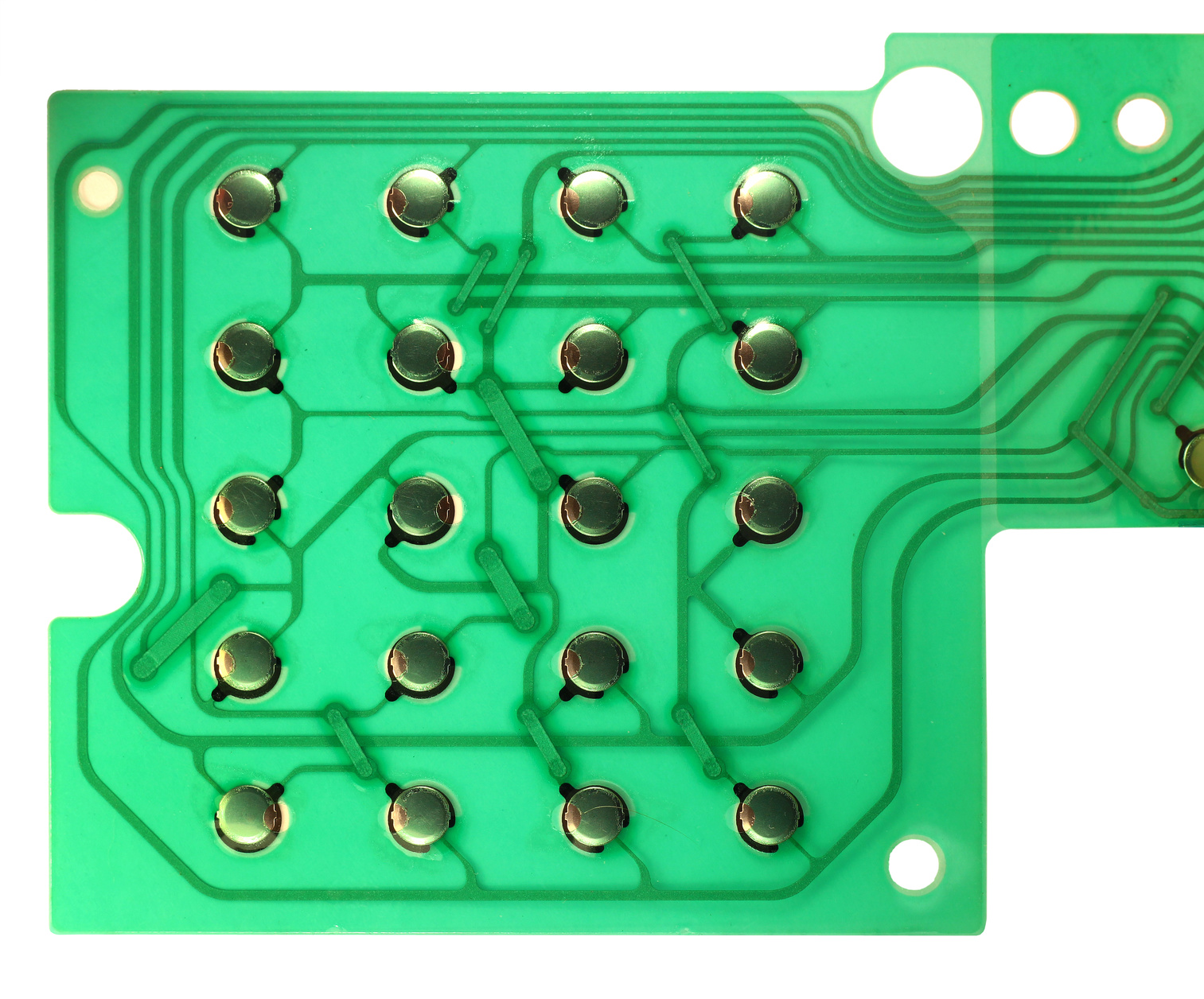

Membrane layer switches are cutting-edge user interface tools that assist in customer communication with digital devices. These functional parts consist of multiple layers, including a visuals overlay, spacer, and a printed circuit layer. The design enables for a seamless combination into different electronic gadgets, enhancing both the visual and functional facets of customer interfaces.

Membrane buttons are generally utilized in a wide variety of applications, from house devices to commercial machinery and medical tools. Their building generally includes a thin profile, making them an excellent choice for small styles. The responsive responses supplied by these buttons can be engineered to satisfy specific customer choices, ensuring effective interaction between the individual and the gadget.

Durability is another substantial advantage of membrane layer buttons, as they are immune to dust, dampness, and chemicals, which boosts their life expectancy popular settings. In addition, these switches can be personalized in terms of form, dimension, and graphic design, allowing for branding and user-specific attributes. Overall, membrane layer changes stand for a functional option for improving customer experience in electronic tools, combining capability with aesthetic charm in a reliable way.

How Membrane Switches Job

Operating on an uncomplicated concept, membrane layer switches use a layered construction to sign up individual input effectively. Each switch includes multiple layers, including a printed circuit layer, a spacer layer, and a top graphic layer, which are made to interact perfectly. When a customer presses the leading layer, it presses the spacer layer, bringing the conductive components of the circuit layer into contact with each other.

This contact produces a shut circuit, signaling the device to implement a details feature. The style permits different configurations, including tactile responses, which can enhance the user experience by supplying a physical experience upon activation. The materials used in membrane buttons often consist of versatile substratums, such as polyester or polycarbonate, which guarantee durability and durability versus damage.

Secret Advantages of Membrane Buttons

One more significant benefit is their density. Membrane switches are thin and light-weight, which enables makers to conserve space in their devices without compromising functionality. This function is particularly valuable in applications where weight and volume are vital considerations.

In addition, membrane layer buttons are resistant to dust, moisture, and chemicals, boosting their resilience. This strength extends their life expectancy and reduces the requirement for constant replacements, resulting in expense savings with time.

Moreover, the tactile comments given by membrane switches can be enhanced to enhance customer communication. They can include attributes such as raised buttons or audible clicks, enhancing usability and individual experience.

Applications Across Industries

User user interface devices utilizing membrane switches prevail in a vast variety of sectors, showcasing their adaptability and capability. Membrane Switch. In the clinical market, membrane switches are integral to tools such as diagnostic equipment and patient monitoring systems, where their toughness and ease of cleansing are essential for preserving hygiene requirements. Similarly, in the automotive sector, these buttons are employed in control panel controls and infomercial systems, providing a streamlined and contemporary interface for customers.

Additionally, the customer electronic devices industry gain from membrane buttons in devices and portable gadgets, where compact layout and straightforward interfaces boost individual experience. Industrial applications also take advantage of membrane switches for control panels in machinery and automation systems, stressing their effectiveness and resistance to extreme atmospheres.

In the aerospace and defense sectors, membrane switches are utilized in cabin controls and equipment, where reliability and efficiency under extreme conditions are critical. In addition, the pc gaming industry increasingly incorporates membrane layer buttons in controllers and game equipments, contributing to an engaging individual experience. Generally, the versatility of membrane layer switches enables their prevalent use throughout countless industries, highlighting their value in modern individual interface layout.

Future Fads in Membrane Layer Switch Over Innovation

Furthermore, the use of sophisticated products, such as polycarbonate and polyester films, is expected to rise, providing improved sturdiness and resistance to ecological stressors. These products add to the overall durability of membrane layer switches, making them suitable for harsher commercial applications.

Additionally, the incorporation of wise technology, including IoT connectivity, will certainly enable membrane buttons to interact with various other tools and systems, helping with a much more interactive user experience. This trend straightens with the expanding need for wise devices across different markets, from health care to customer electronics.

Finally, customization choices are prepared for to increase, enabling producers to develop bespoke solutions customized to particular individual demands and choices. These advancements will position membrane layer switches as vital elements in the advancement of individual interface modern technology.

Verdict

To conclude, membrane changes represent an essential improvement in interface modern technology, offering a reliable and flexible solution for diverse digital applications. a knockout post Their layered building helps with compact layout, while features such as tactile comments enhance user communication. The longevity versus environmental aspects better strengthens their energy across several industries. As improvements in material science and touch picking up technologies continue, the functionality and applicability of membrane buttons are anticipated to increase, enhancing their value in sites contemporary electronic gadgets.